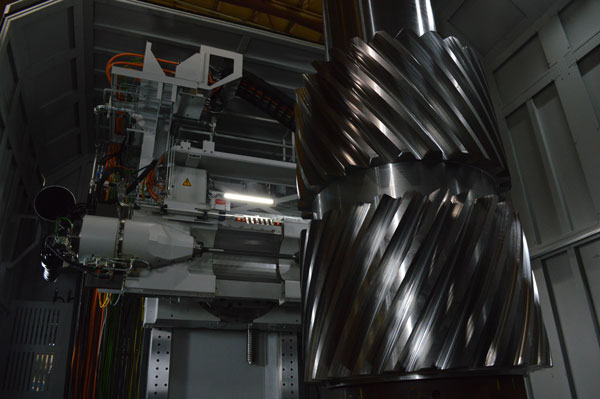

Pinions.

HMC is able to provide carburized and through-hardened pinions that are currently installed and performing in production environments such as power plants, cement plants, processing mills, tug boats, and other facilities and equipment all over the world.